High performance steel wire mesh

3STUTOR® steel wire mesh is obtained by an innovative manufacturing process developed and patented by 3SGEOTECH®.

This process produces high strength wire mesh which shows an excellent mechanical behavior. 3STUTOR® wire mesh is appropriate to be installed in structural applications, where high strength flexible membrane with low deformation under external load application is required.

Some of the common applications for 3STUTOR® steel wire mesh are the following:

- · As a support membrane inside a slope stabilization system.

- · As main catchment surface inside a rockfall protection barrier.

- · As a protective surface for industrial applications and high security fences.

High tensile strength and punching strength

3STUTOR® wire mesh is manufactured with medium carbon steel wire which always offers a guaranteed nominal tensile strength less than 1.000 N/mm2. This wire, specially produced for 3SGEOTECH® with special treatment during the wire drawing, shows a better behavior for bending process in comparison with high yield strength steel wire. This special steel wire has a reduced loss of strength during the wire mesh manufacturing process and under terrain loads.

This particular property of the steel wire together with the special geometry of 3STUTOR® wire mesh, gets high performance membrane with high tensile and punching strength. In fact, punching strength is 1,54 times higher than the one offered by other steel wire meshes produced using high yield strength steel wire (high carbon content wires), even when they offer the same tensile strength.

Low deformation in working conditions

Due to its patented manufacturing process, 3STUTOR® steel wire mesh is unique and different far away from any mesh in the market. The 3STUTOR® mesh is submitted during its production to a pre-tensioning process to reduce deformation in working conditions.

This innovative process, applied during the manufacturing process, allows reducing more than 80% the mesh deformation in working conditions compared with the mesh without this treatment. The final product which is obtained has low deformation under loads, 2 or 3 times less deformation than any high performance mesh in the market.

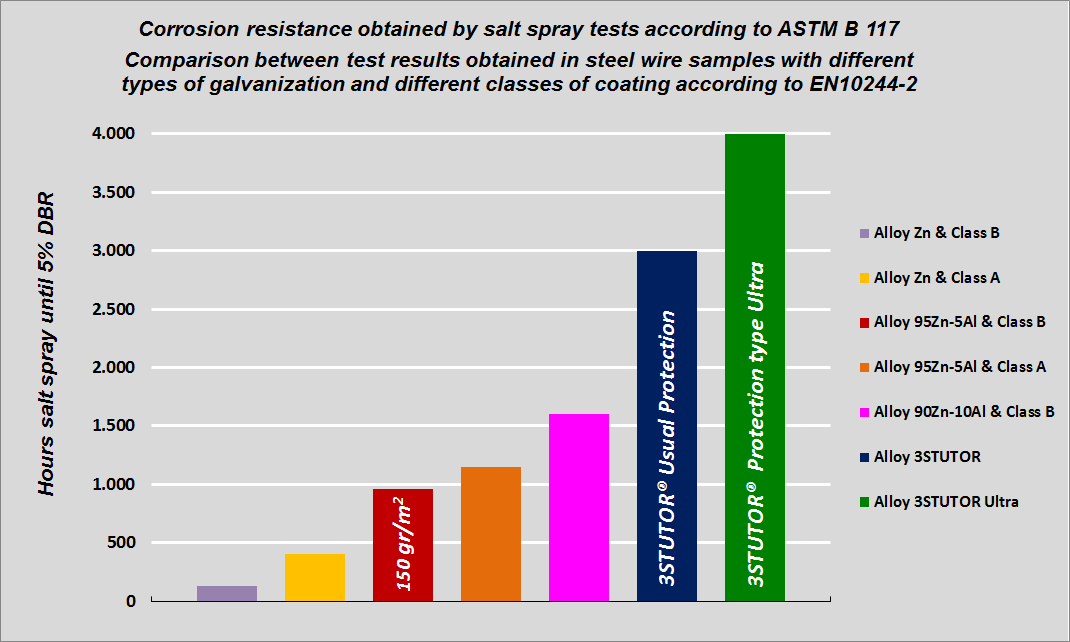

The best corrosion protection in the market

To produce usual 3STUTOR® mesh it is used a steel wire specially produced for 3SGEOTECH® with a specific alloy and coating thickness. This steel wire shows a corrosion resistance higher than the Class A level established by the European standard EN 10244-2. So this steel wire shows a corrosion protection and durability higher than any other steel wire now in the market used to produce high performance mesh.

In addition, it could be possible to produce 3STUTOR® steel wire mesh with a special alloy type Ultra, which offers even higher corrosion protection than our standard production. In this way, this Ultra Coating Treatment guarantees higher corrosion protection and durability, even in the most extremely corrosive environments.

Characteristics of 3STUTOR® steel wire mesh

| Mechanical characteristics of the mesh 3STUTOR® Plus | |||||||

|---|---|---|---|---|---|---|---|

| Mesh type 3STUTOR® Plus | 100/2,7 | 90/2,7 | 100/3,4 | 100/4,0 | 100/4,5 | 90/4,5 | 70/4,5 |

| Diameter of the steel wire, (mm) | 2,7 | 2,7 | 3,4 | 4,0 | 4,5 | 4,5 | 4,5 |

| Minimum tensile strength of the wire guaranteed, (N/mm2) | 900 | ||||||

| Tensile strength of the mesh (T y Breaking),(kN/m) | 55 | 60 | 100 | 135 | 170 | 205 | 260 |

| Punching strength of the mesh (Tp),(kN) | 30 | 30 | 55 | 70 | 100 | 100 | 130 |

| Types of corrosion protection | 3STUTOR® Plus / 3STUTOR® Plus Ultra | ||||||

| Minimum corrosion resistance obtained in salt spray test according to ASTM B 117, DIN SS 50021 | 3.000 hours / 4.000 hours | ||||||

| Minimum equivalent durability in environment class C2 according to EN ISO 9223 | 300 years / 400 years | ||||||

| Type of protective coating according to EN-10244-2 | Over than "Class A" | ||||||